Introduction to the Issue: “New Distributor Crank Super High Idle Problem”

A high idle, an issue where an engine runs unusually fast while the vehicle is stationary, is not just a minor inconvenience. It can significantly affect fuel efficiency, increase engine wear, and impact overall performance.

Sometimes, it might even trigger error codes or warning lights on the dashboard, indicating the urgency of the issue.

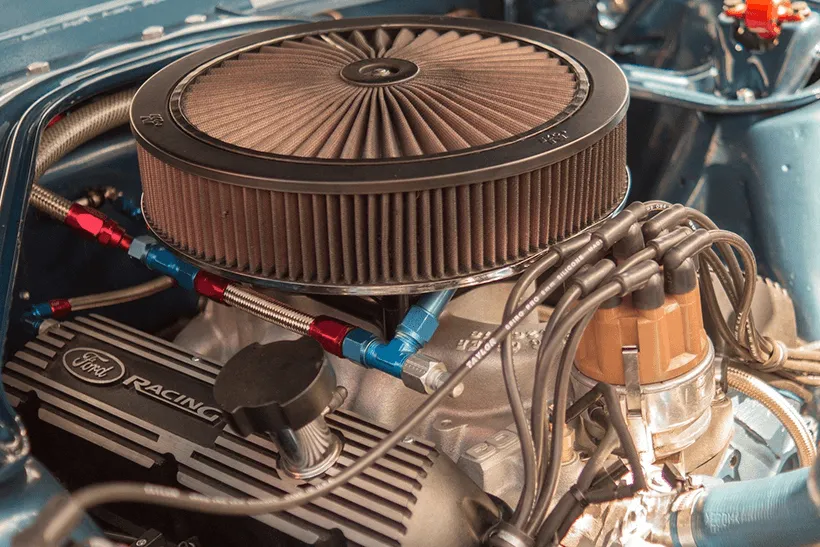

The distributor manages an engine’s timing by directing the spark to each cylinder. If you’ve recently installed a new distributor, it could cause a big idle problem due to incorrect timing adjustments or mismatched components.

This happens because the distributor directly affects engine synchronization, and misalignment can disturb idle speed.

How the Distributor Affects Idle Speed:

- Incorrect Timing Settings: A poorly adjusted distributor can delay engine timing, leading to excessive RPMs.

Vacuum Leaks During Installation: Disturbed vacuum lines or seals can introduce air leaks, raising idle speeds abnormally. A vacuum leak occurs when air enters the engine that has not been measured by the airflow sensor, leading to a lean air-fuel mixture and higher idle speeds.

Sensor Issues: Many modern vehicles use electronic distributors that interface with the ECU. The ECU, or Engine Control Unit, is a crucial component that receives data from various sensors and uses it to calculate the ideal ignition timing. Faulty sensor data can lead to miscalculated idle speeds, resulting from a malfunctioning ECU or the sensors themselves.

Proper diagnosis and understanding of the relationship between the distributor and idle behavior are not just important, but critical for efficiently resolving this issue. Your expertise is key in this process.

| Possible Causes of High Idle | Impact on Engine |

|---|---|

| Incorrect distributor timing | Leads to inefficient combustion and elevated idle speeds. |

| Air or vacuum leaks near distributor | Causes unregulated airflow, increasing engine RPM. |

| Faulty or mismatched distributor components | Mismatched parts can disrupt synchronization, affecting idle. |

| ECU/Idle Air Control Valve malfunction | The electronic control system may misinterpret the idle speed, leading to high RPM. |

For further details, adjusting the distributor timing or inspecting vacuum lines during the replacement process can address the “new distributor crank super high idle problem“ effectively.

Understanding the Problem: “New Distributor Crank Super High Idle Problem”

What Causes a Super High Idle After Distributor Replacement?

Replacing a distributor can sometimes result in a super high idle speed. This issue may arise due to several common reasons:

- Faulty Distributor Installation or Misalignment

- The distributor controls the engine’s ignition timing. Incorrect installation or alignment can throw off the timing, causing the engine to idle at unusually high RPMs.

- Idle Air Control Valve (IACV) Malfunction

- If the IACV is not functioning correctly or is dirty, it can fail to regulate airflow properly, leading to high idle speeds.

- Vacuum Leaks

- During distributor replacement, hoses might be disconnected or damaged, allowing unregulated air into the system. This can disrupt the fuel-air mixture and increase idle speed.

- Throttle Position Sensor (TPS) Issues

- The TPS ensures accurate throttle blade positioning. If disturbed during the distributor’s replacement, it might send incorrect signals, causing high idle RPM.

- Incorrect Ignition Timing Adjustment

- After installing the new distributor, poor timing adjustments can affect how the engine performs, often leading to a higher idle.

How Distributor Timing Affects Idle

The distributor manages the engine’s ignition timing, directly influencing idle speed. Here’s how timing missteps can lead to a high idle:

- Timing Advance Mechanisms

- Distributors may use a vacuum or advanced mechanical systems. If these mechanisms are misaligned, they can result in excess timing advance at idle, causing a high RPM.

- Common Timing Adjustment Errors

- Skipping steps like checking timing marks or improperly using a timing light can lead to excessive ignition advance, resulting in a high idle.

Troubleshooting the Issue

To assist in diagnosing and resolving the ‘new distributor crank super high idle problem ‘, a comprehensive table summarizing the possible causes and solutions is provided below.

| Cause | Description | Suggested Fix |

|---|---|---|

| Faulty installation | Distributor misaligned or not secured properly. | Reinstall or realign distributor. |

| Idle Air Control Valve (IACV) | Malfunction or dirt accumulation affects airflow regulation. | Clean or replace the IACV. |

| Vacuum leaks | Damaged or disconnected hoses introduce unregulated air. | Inspect and reconnect all vacuum hoses. |

| Throttle Position Sensor | Misadjusted TPS sends incorrect throttle blade position data. | Calibrate or replace the TPS. |

| Incorrect ignition timing | Timing too advanced due to poor adjustments during replacement. | Use a timing light to adjust to the manufacturer’s specifications. |

Addressing these causes systematically should help resolve the issue. If the problem persists, consult a mechanic for further diagnostics.

Diagnostic Steps for the “New Distributor Crank Super High Idle Problem”

When dealing with a high idle issue after replacing a distributor, it’s essential to follow a structured diagnostic process to identify and resolve the root cause. This guide will walk you through the crucial steps:

- Initial Checks

- Verify Proper Distributor Installation

- Ensure the distributor is correctly aligned with the engine’s timing marks. Incorrect alignment can lead to a misfire, poor fuel economy, and engine damage, causing the engine to idle at a higher RPM than expected. Inspect for Vacuum Leaks

Look for loose, disconnected, or cracked vacuum hoses. You can use a smoke machine or a can of carburettor cleaner to help identify leaks. A vacuum leak can allow unmetered air into the engine, significantly increasing idle speed.

- Check the Idle Air Control Valve (IACV)

The Idle Air Control Valve (IACV) plays a significant role in regulating idle speed by controlling airflow. If it gets stuck or is improperly reinstalled, it can cause a serious idle problem.

- Testing Ignition Timing

- Use a Timing Light

Connect the timing light to your vehicle as per the manufacturer’s instructions. Shine the light on the timing marks while the engine is running. It’s crucial to compare the observed timing to the recommended specifications in your car’s manual. This will guide you in adjusting the distributor if necessary to match the required settings.

Check Timing Advance Mechanisms

- If your vehicle has mechanical or vacuum timing advances, ensure they are functioning correctly. Faulty mechanisms can lead to incorrect ignition timing, which can affect idle.

- Advanced Diagnostics

Use an OBD-II Scanner

- For modern vehicles, plug in an OBD-II scanner to check for error codes. These codes can provide clues about issues with the IACV, throttle position sensor, or other related components.

- Inspect Related Components

- Examine spark plugs, ignition wires, and the throttle body for signs of wear, damage, or contamination. Cleaning the throttle body can sometimes resolve idle issues.

Diagnostic Data Table

| Step | Tools/Actions Needed | Possible Outcome |

|---|---|---|

| Distributor Installation | Visual inspection, basic tools | Misalignment causes timing issues, leading to high idle. |

| Vacuum Leak Inspection | Carb cleaner, vacuum diagram | Identifies leaks causing unmetered air intake. |

| Idle Air Control Valve Check | Multimeter, cleaning tools | Dirty or stuck valve increases idle speed. |

| Timing Adjustment | Timing light | Aligns ignition timing to manufacturer specs. |

| OBD-II Scanning | OBD-II scanner | Pinpoints sensor or system faults contributing to issues. |

By following these steps, you should be able to diagnose and resolve the “new distributor crank super high idle problem” efficiently. If the issue persists, consult a professional mechanic for more detailed inspections and repairs.

Troubleshooting and Solutions for the “New Distributor Crank Super High Idle Problem”

When faced with a new distributor crank super high idle problem, the following troubleshooting steps and solutions can help you identify and fix the issue effectively:

Step-by-Step Solutions

- Correct Distributor Installation

- Ensure the distributor is installed in alignment with the engine’s timing marks. Misalignment during installation can affect ignition timing, leading to high idle.

- Confirm that all wiring and connections to the distributor are secure and properly placed.

- Clean or Replace the Idle Air Control Valve (IACV)

- A dirty or malfunctioning IACV can restrict air regulation, causing idle speed issues. Remove the valve, clean it with a carburettor cleaner, or replace it if necessary.

- Adjust the Throttle Settings and Calibrate the TPS

- Inspect the throttle body and ensure it’s clean and carbon deposit-free.

- Check the throttle position sensor (TPS) for proper calibration. Use a multimeter to verify its voltage matches the manufacturer’s specifications.

- Fix Vacuum Leaks

- A common cause of high idle is vacuum leaks, which can occur if hoses are improperly reconnected during distributor replacement. Use a vacuum gauge to detect leaks and seal them appropriately.

When to Seek Professional Help

- Complex Timing Adjustments

- Adjusting ignition timing requires precision tools like a timing light and in-depth knowledge of the engine’s specifications. Consulting a professional is best if timing adjustments don’t resolve the high idle.

- Faulty Internal Distributor Components

- Problems with springs, bushings, or the distributor shaft can require specialized repairs or replacement. If these components are suspected, seek expert assistance to avoid further complications.

Example Troubleshooting Data Table

| Problem Cause | Symptom | Solution |

|---|---|---|

| Distributor Misalignment | Rough engine start, high idle | Reinstall and align the distributor correctly. |

| IACV Malfunction | Erratic idle speed | Clean or replace the IACV. |

| Throttle Body Issues | Clean the throttle body and calibrate TPS. | Clean throttle body and calibrate TPS. |

| Vacuum Leak | Whistling sound, high RPM at idle | Identify leaks using a smoke test or vacuum gauge, then repair leaks. |

| Incorrect Timing Adjustment | Persistent high idle after adjustments | High idle when the engine warms up |

Summary

Troubleshooting the new distributor crank’s super high idle problem involves systematic checks of the distributor installation, timing settings, air control components, and vacuum system. While many fixes can be done at home with essential tools, persistent or complex issues often require professional expertise to prevent further engine damage.

If you’re uncertain about tackling these issues, remember that it’s always better to contact a certified mechanic for assistance. Don’t hesitate to ask for help when needed.

Preventative Measures for Avoiding the New Distributor Crank Super High Idle Problem

Prevention is critical when dealing with a new distributor crank with a big idle problem. Your competence and skill in implementing proper installation techniques can help you avoid this issue in the future. Here’s how:

- Regular Maintenance of Ignition Systems: As a responsible automotive technician or DIY enthusiast, it’s crucial to keep your ignition systems in top condition. Regular maintenance is not just a task, but a proactive measure to ensure the smooth operation of your vehicle.

- Distributor Cap and Rotor: Inspect the cap for cracks, corrosion, or carbon tracking. Replace it if it shows signs of wear. Regularly check and clean the rotor tip to ensure optimal spark delivery.

- Spark Plug Wires: Keep wires clean and free from damage. Check their resistance using an ohmmeter to ensure no breaks in conductivity.

- Ignition Timing: Periodically verify timing with a timing light to ensure it’s within the manufacturer’s recommended range.

- Vacuum System: Inspect hoses for wear or damage and replace any leaking ones.

- Tips for Proper Distributor Installation

- Follow Manufacturer Instructions: You’re not alone in this. Always use the installation guide specific to your distributor and engine type. This guidance ensures that you’re on the right track.

- Mark the Position: Before removing the old distributor, mark its position and rotor alignment. This helps with the correct placement of the new one.

- Avoid Over-Tightening: Secure the distributor firmly, but avoid over-tightening as this can lead to misalignment.

- Check Timing After Installation: Use a timing light to confirm that the new distributor is correctly aligned with the crankshaft.

Preventative Maintenance Checklist

| Component | Maintenance Action | Frequency |

|---|---|---|

| Distributor Cap | Inspect for cracks and replace if necessary | Every 12 months |

| Rotor Tip | Clean and check for corrosion | Every 6-12 months |

| Spark Plug Wires | Test resistance and inspect condition | Every 12 months |

| Ignition Timing | Inspect for cracks and replace them if necessary | Every 6 months |

| Vacuum Hoses | Inspect for leaks and replace if damaged | Verify and adjust with a timing light |

Maintaining your ignition system and carefully installing a new distributor can avoid issues such as a super high idle after replacement. If problems persist despite these steps, it may be time to consult a professional technician for advanced diagnostics and repairs.

Conclusion: Addressing the “New Distributor Crank Super High Idle Problem”

As a car enthusiast and DIY mechanic, your role in addressing a high idle issue after installing a new distributor is crucial. Your actions can prevent unnecessary strain on engine components, reduce fuel consumption, and avoid potential long-term damage, thereby maintaining your engine’s health.

Key Takeaways:

- Always ensure proper installation, which includes correctly aligning the distributor and setting the ignition timing, when working on a distributor to prevent the ‘new distributor crank super high idle problem.’Following diagnostic steps, such as checking for vacuum leaks, testing the idle air control valve (IACV), and verifying ignition timing, can help pinpoint the root cause of high idle.

- Regular maintenance and preventive measures, such as checking for vacuum leaks during routine inspections, can help avoid these problems in the future. If these troubleshooting steps don’t resolve the issue or if the adjustments seem too complex, it is highly recommended that you consult a professional mechanic. Their expertise ensures that the problem is accurately diagnosed and corrected before it leads to more severe complications.

By staying proactive and thorough, you play a vital role in maintaining your engine’s performance and reliability. Your efforts can help you avoid costly repairs down the line, making you an integral part of your car’s maintenance.